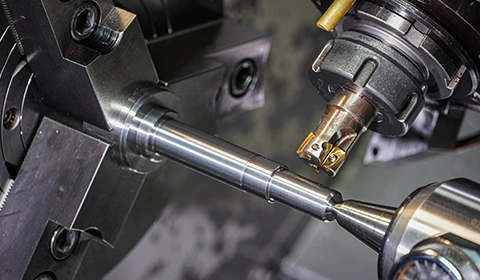

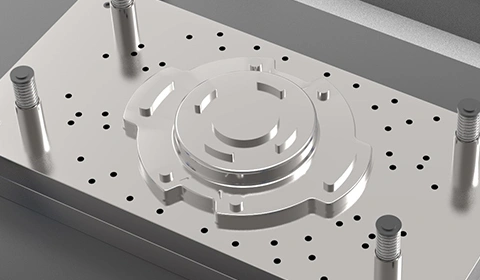

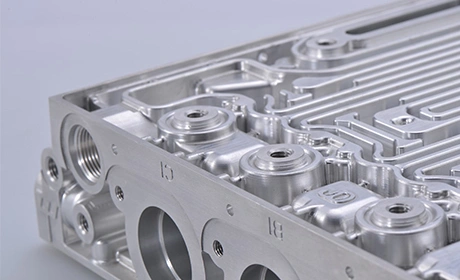

ミルターン複合加工センター、標準3軸、連続5軸、3+2軸フライス盤、穴あけおよび後処理

50 種類以上の素材と 12 種類以上の表面処理。

加工精度:±.0000394インチ(0.001mm)、1.5umグレードの高精度検査センターを装備

ミルターン複合加工センター、標準3軸、連続5軸、3+2軸フライス盤、穴あけおよび後処理

50 種類以上の素材と 12 種類以上の表面処理。

加工精度:±.0000394インチ(0.001mm)、1.5umグレードの高精度検査センターを装備

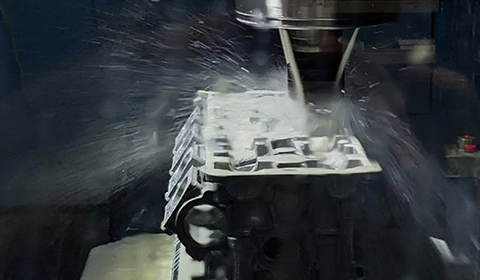

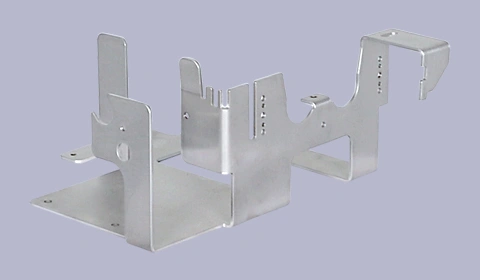

レーザー、プラズマ、ウォータージェット切断、穴加工、曲げ、ストレッチ成形、金属スピニング

40t-750tのスタンピング設備、AGV、MIG、TIG溶接

サイズ範囲: 0.19*0.19*0.011インチ - 51.18*78.7*15.74インチ (5*5*0.3mm - 1300*2000*400mm)

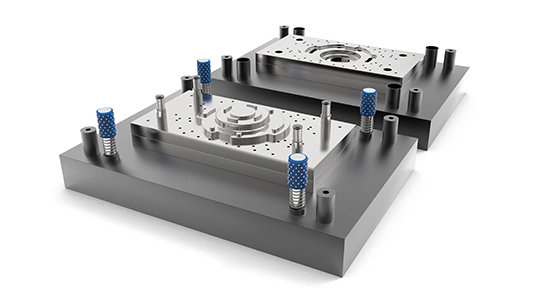

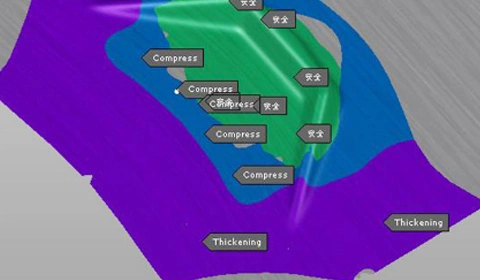

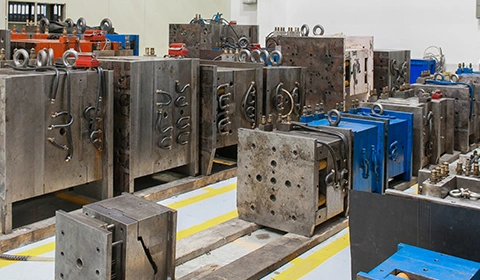

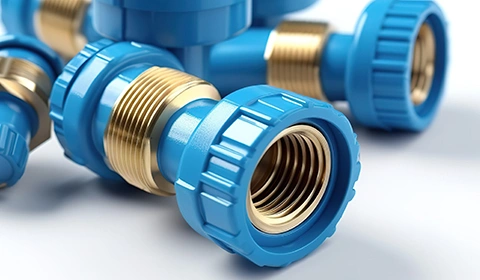

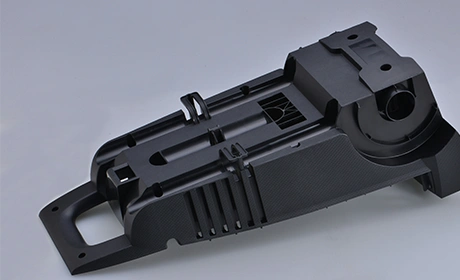

コンピュータ支援エンジニアリング(CAE)、製造設計(DFM)、スタックモールド、2K射出成形、熱間および冷間ダイカスト

高精度金型クランプマシン、ワイヤーカット放電加工機、高速および低速ワイヤーカット放電加工機、高効率CNCスパークマシン

40t-750tの複雑なダイカストの自動生産、長寿命:100万回、硬度:30-60時間

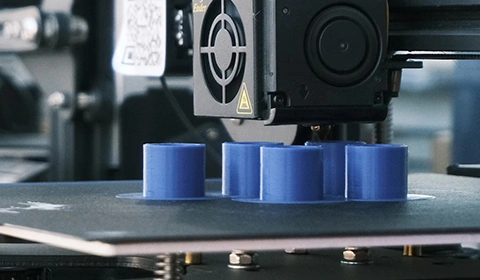

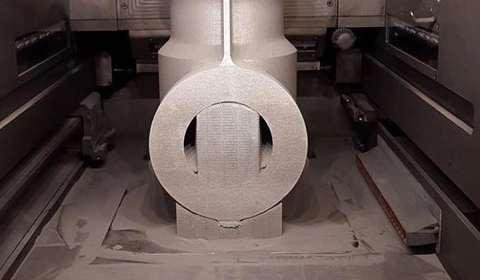

FDM、SLS、MJF、SLA、SLM

材質: 35 種類の材質 (硬質および軟質プラスチック、エラストマー、金属など) から選択できます。

表面処理:染色、メディアタンブリング、サンドペーパー研磨など

許容範囲: ±0.0008 インチ (0.020 mm)

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.